- v50 information can now be added to pages in the main namespace. v0.47 information can still be found in the DF2014 namespace. See here for more details on the new versioning policy.

- Use this page to report any issues related to the migration.

DF2014:Ceramic industry

| This article is about an older version of DF. |

The ceramic industry produces a variety of goods used for trade, storage, constructions, and decoration in support of a fortress. Although the industry produces a fairly limited variety of goods when compared to others, ceramic goods are naturally worth three to ten times the value of similar goods made from common stone or wood, making them a lucrative option for wealth creation. Ceramic goods are divided into three distinct categories (called wares) based on the raw materials used. Earthenware items are produced from generic clay, stoneware from fire clay and porcelain from the stone kaolinite. In order to ensure watertight earthenware containers (jugs and large pots), as well as to increase overall item value, earthenware items require an additional production step called glazing. The ceramics industry also produces gypsum plaster which is critical for dwarven healthcare. Pearlash, a critical production material for the glass industry, is also created as a crossover material from the ceramic industry.

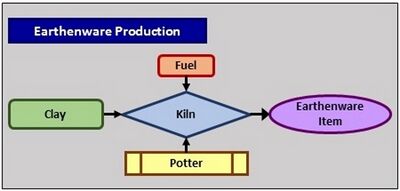

All ceramic goods are produced by a potter at a kiln which requires a fuel source. Regardless of material category, the specific goods that can be produced are: jugs, large pots, bricks (clay blocks), statues, crafts, and beehives. Gypsum plaster and pearlash are also created at a kiln, but use the furnace operator instead of the potter labor.

Industry requirements: resources, facilities, and labor

- Resources: Clay, Fire clay, Kaolinite, Ash (from Wood), Cassiterite, and fuel

- Facilities: Kiln or Magma kiln, Wood furnace

- Labors: Item hauling, Potter, Furnace operator, Glazer, Mining (for Porcelain / fuel), Wood cutting (for fuel).

- Crossover industry requirements: Gypsum plaster stone: gypsum, alabaster, selenite, or satinspar; Potash (for Pearlash)

Categories of ceramic wares

Earthenware

Earthenware ceramics are made using generic clay which can be collected from any generic clay soil tile using the clay collection activity zone, which are typically the most abundant and readily available ware type. Earthenware items have a base value of 3☼ (equivalent to the highest value stone - obsidian). Earthenware items are not waterproof, and as such require a finishing step of glazing should the intended final use require liquid storage. Glazing can also be used to increase the value of the item. Glazed earthenware products can take a considerable toll on your wood resources, in particular if you are using wood for fuel as well as the glazing material (ash).

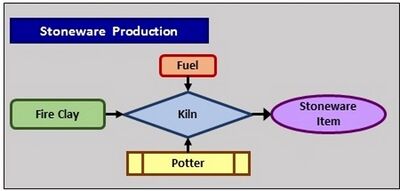

Stoneware

Stoneware ceramics can only be made from fire clay, which is a fairly rare type of soil. As with generic clay, fire clay is collected using the clay collection activity zone. Stoneware items have a base value of 4☼. They do not require glazing in order to be waterproof.

Porcelain

Porcelain ceramics can only be made from kaolinite, a dark red magma-safe stone which may be found in large clusters in sedimentary layers. It must be mined rather than collected, making it a finite resource, (similar to crystal glass as used in the glass industry). Porcelain items have a value multiplier of 10x (equivalent to silver.) Porcelain items are naturally waterproof (do not require glazing). While the stone itself is magma safe, porcelain blocks are not.

Gypsum plaster

Gypsum plaster, while technically not a direct product of the ceramic industry, is produced at a kiln, and can be included in your ceramic industry layout. Gypsum plaster is used to create casts, which are used for healthcare as an alternative to making and using splints. Gypsum plaster can be created from any of the following stone types: gypsum, alabaster, selenite, or satinspar. The stone, along with an empty bag, must be brought to a kiln where a Furnace operator will pulverize the raw stone and place the plaster powder into the bag for storage.

Earthenware production

Clay collection

Earthenware ceramics require generic clay as the basic raw material. There are several types of soil that provide clay, including clay, clay loam, sandy clay, and silty clay. To collect clay, you will need to do the following:

- Use the Activity zone (i) function and select an area of soil (preferably in a secure, underground area) that contains clay, then select c to ensure that the zone is designated for clay collection.

- Ensure that at least one dwarf has the item hauling labor enabled, which is the labor required to collect clay from a zone.

- Select a Kiln and issue a clay collection order. If you plan on producing a lot of items, it is a good idea to set this order on repeat.

As long as at least one tile of clay is available on your fortress map, you will be able to harvest clay infinitely. Collected clay appears as a boulder (similar to stone boulders) and does not use containers for storage or transport. Once harvested, the collecting dwarf will haul the clay to an appropriate stockpile, if available. If there are no suitable stockpiles, the clay will be left at the collection site.

Firing clay

Earthenware items are produced at a kiln by a dwarf with the potter labor enabled. Select the kiln and then designate the item to be made. There is no requirement to first create items on a potters wheel, so it is assumed that your potter hand throws the items to be made and places them directly into the kiln for firing, which strengthens and hardens the item. Kilns require a fuel source, whereas magma kilns can produce all items using magma as the fuel. A standard kiln will consume one unit of fuel per job. (For a discussion of fuel sources, see the fuel industry.)

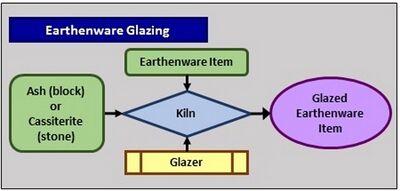

Glazing

Glazing is a process that covers a selected ware with a substance that, when re-fired, results in a glassy, non porous coating which serves to protect the ware, make it impermeable to liquids, and to enhance its visual appeal. Earthenware must be re-fired with a glaze material (or medium), of which there are two types, ash and cassiterite to produce a completed glazed product. Earthenware ceramic containers must be glazed in order to hold water or more importantly booze and oil. Glazing also increases the value of the items, the amount determined by the type of glaze medium used. Glaze mediums are applied at a kiln to jugs, statues, large pots, and crafts made from either stone or ceramics, by a glazer. Earthenware items re-fired in a kiln with 1/150th of a bar of ash produce ash glazed items which adds 50☼ to the items value, though a full bar is required to start the job. Earthenware items re-fired with boulders of cassiterite produce tin glazed items which adds 100☼ to the items value. Cassiterite is an ore which, when smelted, produces tin, and is typically rare, and usually cannot be purchased from caravans. Bars of tin cannot be used to make tin glazes. Note that glazes are not products in themselves, you do not make a glaze and then apply it to the ware. It is effectively a unique (to ceramics and some stone items) form of item decoration.

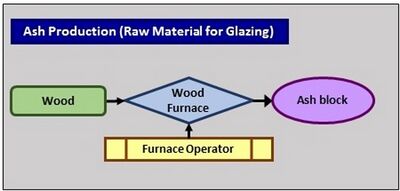

Production of glaze medium

- Ash bars are produced by a wood burner at a wood furnace using the logs of felled trees.

- Cassiterite is an ore of tin, collected by mining. It is typically rare, and when present, is used to support the metal industry.

Stoneware production

Fire clay collection

Stoneware is notable in that it can only be made from fire clay. The collection of fire clay is done in exactly the same manner as regular clay collection.

Firing fire clay

Stoneware items are produced by firing them at a kiln by a dwarf with the potter labor enabled. Kilns require a fuel source, whereas magma kilns can produce all items using magma as the fuel.

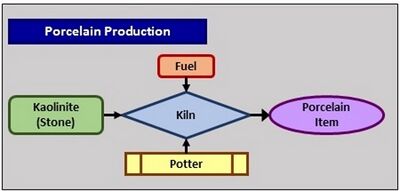

Porcelain production

Kaolinite collection

The stone kaolinite must be mined and collected as with other stone resource gathering. It appears dark red in color, and is a sedimentary stone found in large clusters. The presence of kaolinite and wood or bituminous coal (for fuel) in abundance can result in rapid (sometimes too rapid lots of fun) wealth generation for a fortress. If you do not have any kaolinite readily available, you may be able to procure some through trading. Check with your outpost liaison and request the stone. They probably won't bring a lot, but it will give you something to work with.

Firing porcelain

Porcelain items are produced at a kiln by a Dwarf with the potter labor enabled. Kilns require a fuel source, whereas magma kilns can produce all items using magma as the fuel.

Ceramic industry output

- Jugs and Large Pots: Given that there is considerable work required to use earthenware jugs and large pots for liquid storage (i.e. glazing), it is reasonable to question their utility. One consideration for their use would be the consideration of item weight. Earthenware is the lightest of the three -ware types with a density of 1360, which is much less than almost every type of stone, and all three types of glass (2600). Jet (stone) is the exception, as its density is just below that of earthenware (1320). The lightest normal (not adamantine) metal is aluminum at 2700. Large pots used for booze storage are typically hauled all over your fortress, so the lighter and thereby faster they are, the more efficient they become. So the extra effort of producing glazed earthenware large pots will result in the largest, and effectively lightest liquid containers, (unless, of course, you have gobs of adamantine to spare.)

- Crafts: The ceramic industry is one of the few industries that does not benefit from a nearby craftsdwarf's workshop. As with the metal and glass industries, a unique facility is required to create crafts, and for ceramics this is the kiln. That said, the kiln cannot be used to make ceramic goblets, instruments, or toys.

- Ceramic Bricks (aka blocks): While all ceramic bricks are fire-safe, they are not magma safe (even though porcelain is made from the magma-safe stone kaolinite). Ceramic bricks are 3-10x as valuable as common stone blocks and may be produced in infinite quantities if you have a local source of clay, making them marginally useful for improving the value of roads, bridges, and rooms in soil layers. If kaolinite is set to "non-economic" via the z Stone menu, a mason can convert one kaolinite boulder into four low-value, magma-safe kaolinite blocks instead.

- Statues: If high-value decorative metals (gold, silver, platinum and their alloys) are in short supply, and you are lucky enough to have some kaolinite, porcelain statues can be used to create high-value rooms. The endless nature of earthenware and stoneware statues also makes them suitable for producing in high quantities to achieve the same purpose, or simply to create impressive-looking architecture.

Benefits of skilled labor and strange moods

A skilled potter or glazer will generate items or decorations of a higher value. If fuel is in ready supply, a potter can be quickly skilled up by churning out earthenware craft items. Likewise, while done one at time, ash glazing is very fast with low resource cost. Neither the potter nor glazer labor qualifies for strange moods. It can be worthwhile to give these dwarves some experience in a desirable "moodable" skill like weaponsmith to avoid getting another legendary woodcrafter.

Advanced industry management

- Optimal Clay Collection: A robust ceramic industry will demand a lot of clay, so it is a good idea to put dedicated kiln(s) on repeating collection orders, preferably with nine redundant iterations to prevent the manager from tasking any other production from that kiln. (Or just use the workshop profile) Clay collection is time-consuming, and if you are outstripping your supply you will start to see job cancellations as the potter's increasing skill / speed of production outpaces the clay supply. To ensure a smooth production process, have several dwarves with item hauling enabled for each kiln set to gather clay. Putting the collection zone as close as possible to the operating kiln and collection kilns reduces both hauling and travel time. The zone can be designated right on top of the operating kiln with no ill effects, and reduces the potter’s hauling duties to almost nil. There appear to be no issues with small (1-6 tile) zones with multiple collection kilns, although further research/experience is required.

- Managing your Stocks: Clay is stockpiled under Stone, and each clay boulder takes up a single tile, so it's a good idea to create fairly large clay stockpiles close to your kilns. Wheelbarrows may be useful for collecting clay, but it needs to be determined if a second collection trip occurs for each clay boulder produce in collection, (e.g. one trip to harvest the clay and one to transport it) which might diminish the utility of the wheelbarrow. It may be more efficient to create a stockpile right next to your collection area, and then create a second stockpile next to your kilns, which takes from the first (in which case wheelbarrow use will save time.) Alternatively, quantum stockpiles are a useful space-saving (but management-intensive) alternative. Kaolinite boulders also take up a full tile, so somewhat large stockpiles are useful for that as well.

- Ware Specific Production: If you are fortunate enough to have both generic and fire clay, as well as kaolinite, or you purchase the material from caravans, you will want to control the ceramic item produced by the related ware type. This is challenging, as you can't fine-tune what your dwarves will use through the kiln menu or the manager's screen. You can't tell them exactly what material to fire or what kind of thing to glaze, only what to make and what type of item to glaze. This can be solved by using linked stockpiles or workshop-restricting burrows. Ideally you could create a single kiln for each ware type and link it to a dedicated stockpile. You will also need to link non-magma kilns to a fuel stockpile (you can use the same fuel stockpile for multiple kilns). Workshop-restricting burrows can be set up similarly. Another approach uses the fact that dwarves will usually go for the nearest available resource. Make a custom dedicated stockpile right next to a kiln, isolating the raw material, and you can more or less force the potters to use that material over another. If you only have one production kiln, this has the major disadvantage of requiring you to haul raw material back and forth when you change ware type, as dwarves will have to carry away the no-longer-needed material and carry in the newly desired one. You can also try forbidding the raw materials so dwarves can't make goods from them. This is probably most useful for kaolinite because of its limited availability.

- Glaze Specific Production: If you have lots of wood and cassiterite available allowing for both glaze types, you will face the same production problems as you would with multiple ware source material. Optimally, dedicate one kiln to a stockpile with a specific glaze material (ash or cassiterite), a fuel stockpile, and an earthenware goods stockpile. You can chose (control) the item to be glazed, and by linking the kiln to a specific glaze material stockpile, you will also control the glaze type. It is also useful to keep a wood furnace producing ash and a wood stockpile close by, which should keep your stocks of ash readily available. Ash is produced as a bar, and is stored in bins, so your ash stockpile can be fairly small and still hold a considerable amount of ash. Tin bars can't be used to make tin glazes, so don't smelt cassiterite if you don't need tin bars.

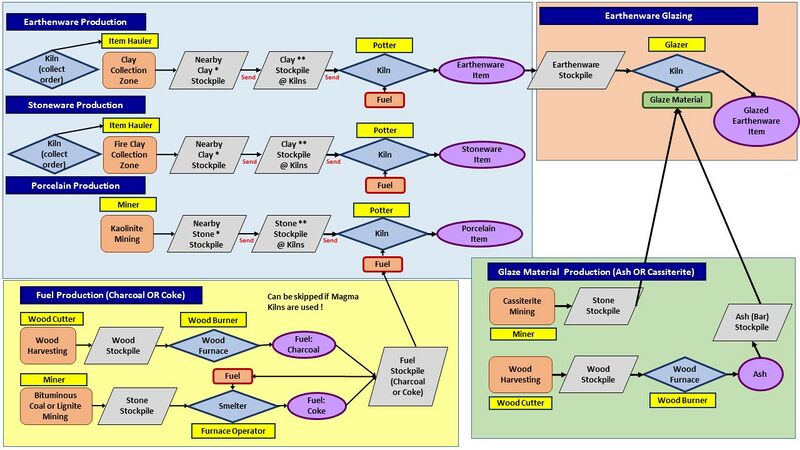

Ceramics industry integrated flowchart

Ceramic industry crossover

- Glass Industry: As there is some natural overlap with the glass industry with regard to materials required, it may be useful to set up your ceramics industry near your glass industry. Potash makers use ash at asheries to produce potash, which in turn feeds kilns that make pearlash, which is used to make clear glass and crystal glass. As ceramics already requires ash production, and uses kilns as the primary production facility, there is some efficiency advantage to be had by keeping the distance between the two industries short.

- Jewelry Industry: Clay can be used by a gem cutter to advance their cutting skill. As clay is effectively unlimited, and as it requires no processing step (unlike glass) in order to be used, it is a very efficient material for training your gem cutters, and it can be transported more quickly than stone. The main drawback is the time it takes for an item hauler to gather the clay.

- Fuel Industry: The ceramic industry relies on fuel to function properly. Until magma becomes available, a steady supply of coke or charcoal will be necessary.

- Wood Industry: The glazing of earthenware products relies on ash. If you plan on developing a large ceramic industry, integration of ash production directly into the ceramics facility layout is recommended.

Notes, tips, and tricks:

- Embark: To ensure that you can set up a basic ceramic industry, make sure that either "clay" or "shallow clay" is shown as available in the embark screen. The specific type of clay available, (such as fire clay) cannot be determined ahead of time, (unless you use DFHack's pre-embark estimate, which is not always accurate.)

- Raw clay boulders can also be used in construction, similar to stone boulders.

- It is possible to create clay soil tiles in areas where there are no naturally occurring tiles. When an underground plant (trees, shrubs, grass or moss) grows on a muddy stone floor tile (after discovering a cavern) and is either trampled, gathered, cut down or removed via building a dirt road on top of it, the floor tile turns into a soil type appropriate to the biome - for biomes which lack soil layers altogether (such as mountains and glaciers), a random soil type will be selected, which might sometimes be clay.

- Ceramics are considered to be fire-safe but typically are not magma safe. Raw clay is not fire-safe.

- Stupid Dwarf Ceramics: Create an oriental themed fortress using porcelain statues, and ceramic blocks for internal construction. Use fire clay to create 1000 Terracotta statues for an elaborate tomb in which to enshrine a dead noble.

|

This article or section has been rated D for Dwarf. It may include witty humour, not-so-witty humour, bad humour, in-jokes, pop culture references, and references to the Bay12 forums. Don't believe everything you read, and if you miss some of the references, don't worry. It was inevitable. |

Being somewhat sensitive as to their height (or lack thereof) in comparison to other sentient races, the ingenious yet vertically insecure Dwarves are prone to compensate for their diminutive stature by making "really big things". Take, for example, the ceramic statue. Given that the average statue is large enough to take up the entire space of a tile upon which it is placed (thereby prohibiting passage), it therefore must be considerably larger than a chest or cabinet (large furniture items which do allow units to pass through), and it can only be surmised that the statues are quite large. It follows that a "really big kiln", (say, 10-12 feet tall) would be required to fire one of these "really big statues" using incredibly accurate temperature control. For a Dwarf, these feats of engineering are taken in (short legged) stride. Given the size, weight, and relative fragility of an un-fired statue, it must be assumed that your basic kiln also includes a crane (or two) and the necessary scaffolding surrounding the kiln that will allow careful placement of the statues within the massive firing chamber.

| Wares | |

|---|---|

| Raw materials | |

| Facilities | |

| Labors | |

| Products | |

| Bugs | |

| Primary | |

|---|---|

| Secondary | |

| Tertiary | |